How Thick Should Engineered Wood Flooring Be? A Complete Guide

Choosing the right engineered wood flooring can feel overwhelming, especially when considering technical specifications like thickness. An engineered wood floor is constructed from several layers, including a plywood core for enhanced stability and durability. As more homeowners opt for this versatile flooring option, understanding thickness requirements becomes crucial for making an informed decision.

Choosing the right flooring depends on the specific rooms in your home and your personal preference for style and function. This comprehensive guide will help you navigate the various thickness options and choose the perfect engineered wood flooring for your space.

Understanding Engineered Wood Flooring Thickness

Engineered wood flooring typically ranges from 10mm to 20mm in total thickness, with wear layers varying between 2mm and 6mm. The top layer is a solid wood veneer, and the wear layer thickness is a crucial factor that determines the floor's durability, lifespan, and ability to be refinished. The total thickness comprises two main components: the solid wood wear layer on top and the engineered core underneath. This structure provides the perfect balance between stability and authentic wood appearance.

The total board thickness and the thickness of engineered wood are important for both durability and suitability for different rooms, as they influence installation, performance, and maintenance.

For homes with underfloor heating, thickness becomes particularly critical. The optimal thickness shouldn’t exceed 18mm, with a wear layer no thicker than 5mm, to ensure efficient heat transfer. Thinner boards, typically around 14-15mm, are more suitable for underfloor heating systems because they conduct heat more efficiently and manage temperature changes better. This specification allows you to enjoy the warmth of underfloor heating while maintaining the beautiful appearance of real wood.

A thicker wear layer and the right thickness of engineered wood can extend the floor's life by allowing for more sanding and refinishing over time.

Specific Thickness Recommendations

Standard Thickness Options

The most popular thickness options are:

-

15mm boards with 3.5-4mm wear layers

-

20mm boards with up to 6mm wear layers

The total board thickness affects the flooring's stability, heat conduction, and suitability for different installation methods. A greater total board thickness can also enhance durability and performance. Additionally, the wear layer thickness is crucial for determining how many times the floor can be sanded and refinished, directly impacting the floor's lifespan and maintenance options.

Each option serves different purposes. The 20mm engineered wood boards can be installed directly onto joists, making them ideal for traditional installations. However, 15mm engineered wood boards require a proper subfloor, making them better suited for concrete floors or modern construction methods.

Installation Considerations

Your choice of thickness should factor in the installation method and location. For instance, 20mm boards offer greater stability when installed directly onto joists, while 15mm options provide more flexibility for different subfloor types.

When installing engineered wood floors, especially in areas with fluctuating temperatures like conservatories, it is essential to leave a wide enough expansion gap around the perimeter. This expansion gap allows for natural expansion and contraction due to changes in temperature and moisture, helping to prevent damage and ensure a neat finish.

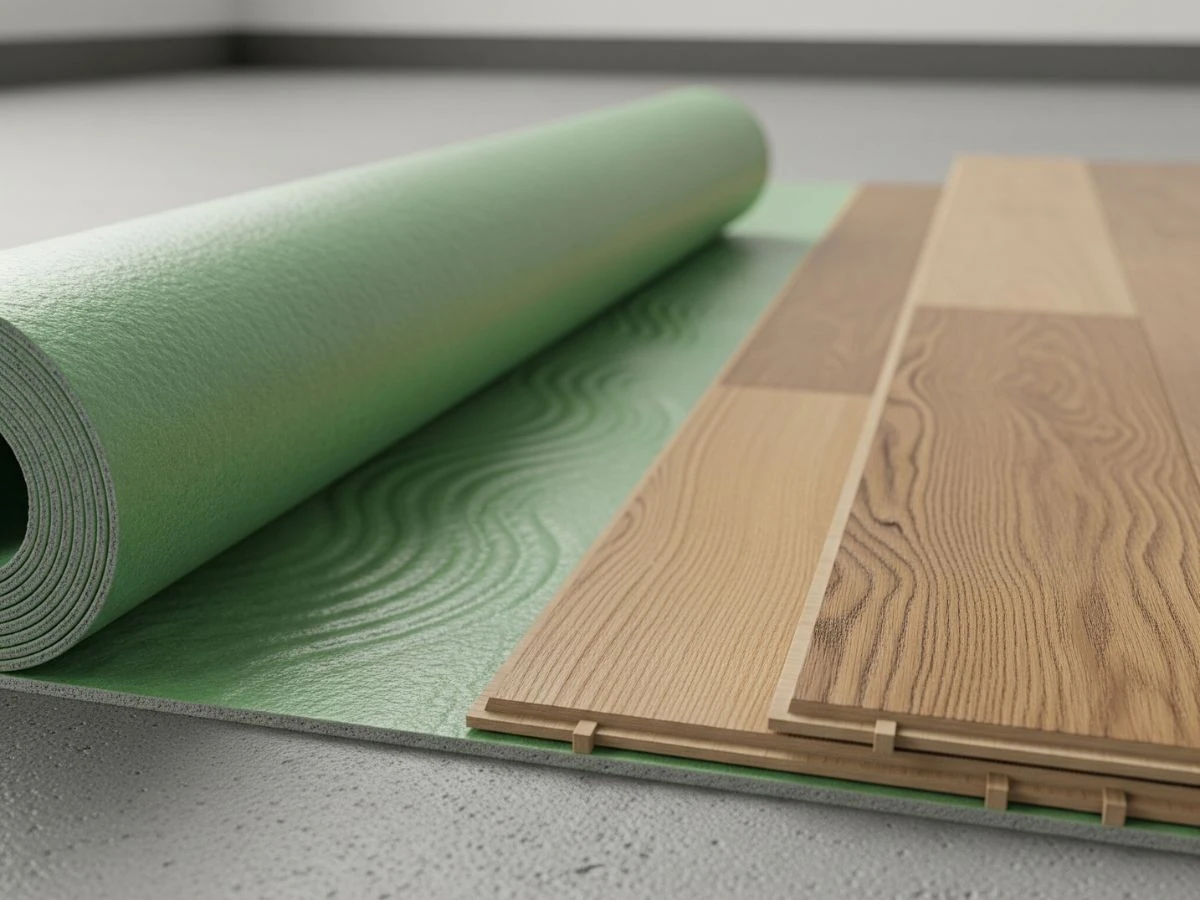

The Role of Subfloor and Underlay

The condition of your subfloor significantly impacts the performance of your engineered wood flooring. A properly prepared subfloor ensures comfort underfoot and optimal sound insulation. Engineered floors are especially suitable for a variety of subfloor conditions, making them a versatile choice for different rooms and installation scenarios. For apartment installations, acoustic underlays are particularly important to minimize noise transmission.

When selecting underlay, consider:

-

Moisture protection requirements (some underlays offer additional protection against moisture and wear)

-

Sound insulation needs

-

Subfloor condition

-

Compatibility with underfloor heating

Choosing the Right Timber

The quality of timber used in your engineered flooring is just as important as its thickness. Look for products with FSC or PEFC certification to ensure sustainable sourcing. Engineered wood flooring is available in a variety of woods, such as walnut, oak, beech, and maple, each offering distinctive grains and natural appearance. These floors feature a solid wood veneer layer, which not only replicates the look of solid wood but also provides durability and allows for sanding and restoration.

At Lumber King, we offer a range of sustainably sourced engineered wood flooring options, and you can order free king-size samples to assess the quality and appearance in your space before making a decision. Finishing techniques like using a wire brush can create a textured surface, enhancing the wood's character and durability.

Considerations for High-Traffic Areas and Moisture-Prone Spaces

High-Traffic Areas

For areas with heavy foot traffic, opt for:

-

Thicker wear layers (4-6mm)

-

Glued-down installation methods

-

Premium quality timber species

Moisture-Prone Spaces

In bathrooms and other moisture-prone areas:

-

Use premium moisture barriers

-

Select engineered wood with enhanced stability

-

Consider thicker boards for better structural integrity

Cost and Budget Considerations

When planning for new engineered wood flooring, understanding the cost and budget implications is essential. Engineered wood flooring is generally more cost-effective than solid wood floors, with prices typically ranging from £20 to £100 per square meter. The final cost depends on several factors, including the type of wood species chosen, the thickness of the wear layer, and the overall quality of the flooring. Thicker wear layers and premium wood species like oak or walnut tend to be at the higher end of the price spectrum, but they also offer greater durability and a longer lifespan.

It’s important to remember that the total investment goes beyond just the flooring itself. Installation costs, underlay, and any necessary subfloor preparation can add to the overall budget. While engineered wood flooring may have a higher upfront cost compared to some other flooring types, its durability and ease of maintenance often make it a more economical choice in the long run. By carefully considering both the initial expense and the long-term value, many homeowners find engineered wood flooring to be a smart and stylish investment for their living spaces.

Maintenance and Repair of Engineered Wood Flooring

Engineered wood flooring is designed for durability and ease of care, making it a popular choice for busy households. Regular maintenance is straightforward: sweeping or vacuuming helps remove dust and debris, while occasional damp mopping keeps the surface looking fresh. It’s important to avoid excessive moisture, as even engineered wood can be sensitive to water over time.

One of the key advantages of engineered wood flooring is its wear layer. Thicker wear layers allow for the floor to be sanded and refinished multiple times, helping to repair scratches, dents, or signs of wear. This means that, with proper care, engineered wood floors can maintain their beauty and functionality for decades. The frequency of sanding depends on the thickness of the wear layer—thicker layers provide more opportunities for refinishing, while thinner layers may require more gentle maintenance. By following recommended cleaning routines and addressing minor repairs promptly, homeowners can ensure their engineered wood flooring remains a durable and attractive feature in their home.

Aesthetic Options in Engineered Wood Flooring

Engineered wood flooring offers an impressive array of aesthetic options, allowing homeowners to create a look that perfectly complements their personal style and the character of their living spaces. With a wide selection of wood species available—including classic oak, rich walnut, and many others—engineered wood flooring can showcase unique grain patterns and natural beauty. Plank widths and lengths can be chosen to suit both traditional and contemporary interiors, while finishes range from smooth and glossy to textured and distressed for added visual interest.

Beyond the natural appearance of different wood species, engineered wood flooring offers further customization through stains, paints, and surface treatments. Whether you prefer a wire-brushed texture, a hand-scraped finish, or a sleek matte look, there are options to suit every taste. This versatility makes engineered wood flooring a popular choice for those looking to enhance their home’s aesthetic appeal while enjoying the practical benefits of modern flooring technology.

Sustainability and Environmental Impact

For environmentally conscious homeowners, engineered wood flooring stands out as a sustainable alternative to traditional solid wood floors. The construction of engineered flooring uses multiple layers of wood, often incorporating fast-growing species like plywood for the core, which helps conserve slow-growing hardwoods. This layered approach not only provides excellent stability but also reduces the demand on old-growth forests.

Many engineered wood floors are produced using reclaimed or recycled wood, further minimizing environmental impact and reducing waste. Leading manufacturers often adhere to strict sustainability standards, such as FSC (Forest Stewardship Council) certification, ensuring that the wood is sourced responsibly and with respect for the environment. By choosing engineered wood flooring, you can enjoy the warmth and beauty of real wood while supporting sustainable forestry practices and making an eco-friendly choice for your home.

Conclusion

Choosing the right thickness for your engineered wood flooring depends on various factors, including installation method, room usage, and subfloor conditions. Generally, 15mm-20mm total thickness with 3.5-6mm wear layers provides excellent durability and performance for most residential applications.

To make the best choice for your space, consider ordering free king-size samples to assess the quality and appearance in your home environment. With proper thickness selection and installation, your engineered wood flooring will provide beauty and durability for years to.

Ready to see the difference quality makes? Don't settle for guesswork when choosing your perfect engineered wood flooring. Get your free samples from Lumber King today and experience the premium thickness, stunning grain patterns, and exceptional craftsmanship in your own home. Our king-size samples give you the confidence to make the right choice – because your dream floors deserve more than just imagination